- Windex Co.,LTD

- Strengths of Windex

Strengths of Windex

What you only have to do is to consult with us.

We understand your needs properly and respond appropriately.

We solve difficult issues on mold and component processing.

1.Support general processed products

Our original specialty is mold, but we are also accepting a variety of jobs concerned with general processed products. You may worry that the costs of processing general processed products may be high in a mold manufacturer, but we can offer reasonable prices suited to the request level of the products.

Of course we are able to offer high-precision products with ease because we are a mold manufacturer.

2.Support plastic molds in a broad range of fields

We have produced products in various fields such as automobile, OA and FA, optics, medical services, foods, cosmetics, and lens, etc...

If the weight of product is under about 250t, we will understand your needs such as the product which requires a special mechanism, the product which requires a micron of correction, multi-cavity mold with dimension error NG between cavities, production model focusing on mold lifetime and continuity,

prototype model focusing on the price and delivery date, and offer products meeting the needs.

3.Ability to meet the needs

We can save the efforts of customers because we have the combination of ability to hear and understand the needs of customers properly, analytical ability and technical ability to solve difficult issues, energy and capacity for judgement to properly utilize the strength of our company and the network of over 30 subcontract factories at home and abroad. If you consult with us, every issue will be solved.

Technical Info

Precision plastic mold

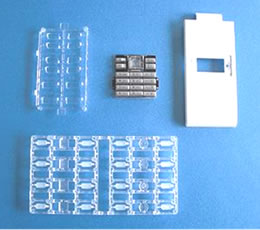

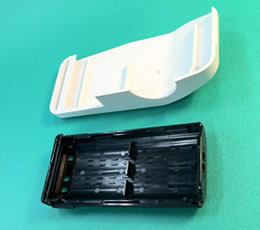

We are dealing with products in every field such as next-generation automobile, next-generation telecommunication, energy, medical service, optics, container, and lens, etc... We are providing a broad range of products regardless of the contents such as the one which requires a special mechanism, the one which requires strict correction, and the one which must be mirror surfaced. We show only a part of molded samples.

- Molded sample (Cell phone)

- Molded sample (Compact)

- Molded sample (Optics)

- Molded sample (Optics)

- Molded sample (Automobile)

- Molded sample (Case)

- Molded sample (Mechanical part)

- Molded sample (Cam)

- Molded sample (PPS)

- Molded sample (Two color)

- Molded sample (Lens)

- Molded sample (Lens)

Metal component processing

We are organized to meet every kind of needs such as precision, delivery date, price, and processing way through the subcontracting factory network including in-company processing in constant temperature factory and overseas factories. Please consult with us regardless of the material or processing contents.

- Plate

- Mold components (Insert die)

- Mold components

- Mold components

Lens mirror plate processing

- Mold components(Lens)

We can also process non-spherical surface and Fresnel. We handle materials from phosphor bronze to tempered material plated and carbide, processing ways from general-purpose to machining and nanomachine to meet the needs. Only mirror surface polishing is also OK.

Electrode processing

- Electrode

We can handle both Erowa and 3R jig. Not only quality but also speed is essential to electrodes, so we mass-produce them speedily. Since we have a lot of experience, we can understand the specifications you require in the shortest meeting. We are confirming precisions such as parallelism, position, and dimension. Of course we can also handle polishing and electric discharge processing.

Facility and equipment components processing

We are handing general processed products regardless of material utilizing the network of in-company and global subcontracting factories to meet the needs such as quick delivery, low price, and high quality.

We also handle polishing and surface processing.

- Facility components1

- Facility components2

Overseas procurement

There is an ever-increasing amount of cost cut demand, so we are under the situation where we can’t help but procure inexpensive components from overseas in order to meet the needs of customers.

We use four languages of Japanese, English, Korean, and Chinese to procure processed products from overseas considering quality, price, and delivery date required.

We manage our risk in overseas procurement with a sense of responsibility.

All of the procured processed products must go through our company’s quality control so that we can deliver Japan-quality products.